Divert Valve Auto Control

- Home

- Divert Valve Auto Control

DIVERT VALVE AUTO CONTROL

- Max. production pressure:10 bar

- Temperature:-10℃ to 140℃ ( EPDM )

- Air pressure:5 bar to 7 bar

- Compressed air:R1/8" ( BSP ), internal thread

- All parts connected with fluid:AISI 316/316L

- Other metal parts:304

- Seal:EPDM / Silicone / Viton ( FKM ) / PTFE

| L | T | Y | F |

|---|---|---|---|

|

|

|

|

| L/L | T/L | L/T | T/T |

|

|

|

|

- The air supply (air pressure)

- The length and dimensions of the air hose

- Number of valves connected to same air hose

- Use of single solenoid valve for serial connection

- Product pressure

Air/Spring (simple effect) or Air/Air (double effect) for auto control can use automatic control box to get signal transfer and complete individual valve control

- Signal transfer:- ⑴ with 10 VDC ~ 30 VDC proximity switch connection: 1 or 2pcs ( PNP or NPN )

- ⑵ or 3A 125 VAC, 30 VDC micro switch connection: 1 or 2pcs

Choose ⑴ or ⑵ + DC24 3.0W electric valve: 1pc & air manifold for complete control box

-

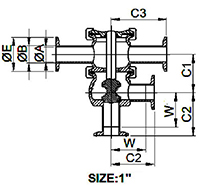

STL-APneumatic Divert Valve T/L-Type

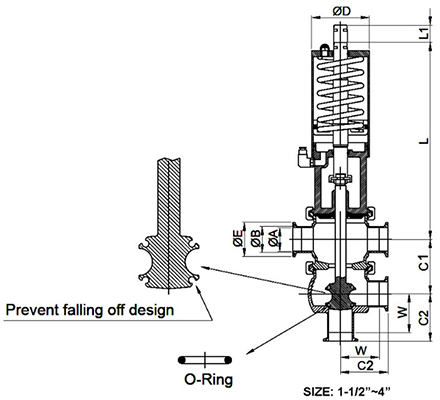

Size ØA ØB ØE ØD C1 C2 C3 W L L1 1” 22.1 25.4 50.5 60 56.7 63.5 81.4 50.8 153.6 17 1-1/2” 34.8 38.1 50.5 85 80.0 69.9 - 57.2 290.0 25 2” 47.5 50.8 64.0 85 92.4 88.9 - 76.2 296.3 25 2-1/2” 60.2 63.5 77.5 133 120.0 88.9 - 76.2 365.8 32 3” 72.9 76.2 94.0 133 128.0 95.3 - 82.6 368.9 36 4” 97.4 101.6 119.0 133 150.8 114.3 - 98.5 645.7 38 -

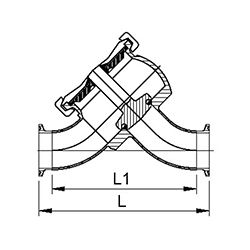

SY-APneumatic Divert Valve Y-Type

SIZE L1 L 1” 96.1 121.5 1-1/2" 142.3 167.7 2” 168.6 194 2-1/2” 211.6 237 3” 244.7 270.1 4” 303.1 334.7

Operation Instruction

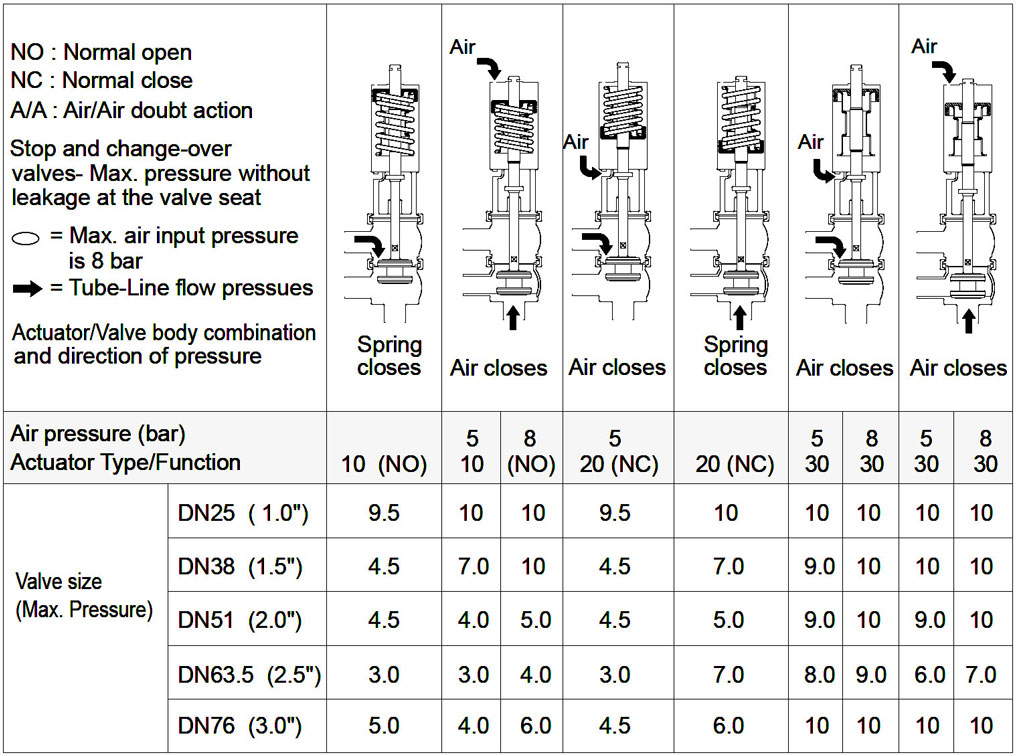

Max. flow tube pressure without leakage of valve seat.

If over table Max. Pressure, adding proof mix. valve is suggested.

Actuator type / function:

(10) SA. Pneumatic downward movement, spring return (NO-lower seat)

(20) AS. Pneumatic upward movement, spring return (NC-lower seat)

(30) AA. Pneumatic upward and downward movement (A/A)

Enhance Process Efficiency With Valves From Control Valve Manufacturers

Delta Fittings offers top-quality control valves manufactured to meet the needs of diverse needs. Our control valves are manufactured utilizing corrosion-resistant materials and advanced manufacturing processes for optimal performance.

Our company has a delicate balance of engineering expertise, craftsmanship, quality materials, and the manufacturing process to achieve the best results. We have been in the industry for the past 30 years, and through our rigorous R&D program, we are able to provide the best solutions for the industry.

As leading control valve manufacturers, we provide pneumatic control valves that find application in all kinds of industries, such as power station construction, chemical plants, pharmaceuticals, foodstuff production and steelworks.

Flow types Of Control valves

At Delta Fittings, we are leading control valve manufacturers in India, offering versatile flow types to meet various industry needs. Our control valves ensure optimal flow control in hydraulic and pneumatic applications:

- L (L-Type Flow Control Valves): We provide L-type flow, which is ideal for right-angle fluid diversion, ensuring precise control and minimal turbulence.

- T (T-Type Flow Control Valves): Our T-type flow allows fluid distribution in three directions for efficient multi-branch flow control.

- Y (Y-Type Flow Control Valves): Delta Fittings delivers Y-type flow and is designed for smoother transitions and reduced pressure drops, ensuring superior flow control.

- F (F-Type Flow Control Valves): We supply F-type flow, combining L, T, and Y elements for flexible and versatile flow control.

- L/L (Double L-Type Flow Control Valves): At Delta Fittings, we offer L/L-type flow for bi-directional right-angle fluid diversion.

- T/L (T and L-Type Flow Control Valves): Our T/L-type flow combines T and L for multi-directional control with right-angle diversion.

- L/T (L and T-Type Flow Control Valves): We provide L/T-type flow, merging L and T types for enhanced flow control and distribution.

- T/T (Double T-Type Flow Control Valves): Delta Fittings delivers T/T-type flow for comprehensive multi-directional fluid distribution.

Key Features Of Delta Fittings Control Valves

As leading control valve manufacturers in India, Delta Fittings offers high-quality control valves with the following features:

Max Production Pressure of control valves: A range of control valves developed by prominent control valve manufacturers, together with advanced features, allow our control valves to work at a maximum production pressure of 10 bar, making them ideal for operations in various industrial sectors.

Temperature Range of control valves: Designed for most applications of temperature IN (-10 to 140℃) with EPDM seals.

Air Pressure of control valves: On average, our control valves’ functionality is optimal when the air pressure is at a range of 5 bar to 7 bar, ensuring sharp and stable control over the flow of fluids.

Compressed Air Connection of control valves: With internal thread connections up to R1/8” (BSP), the mounting of control valves is relatively easy and they can be adapted to existing systems.

Superior Material Quality Of Control Valve Manufacturers

As one of the leading control valve manufacturers in India, Delta Fittings prioritizes using high-grade materials to ensure the durability and reliability of our valves:

Parts in Contact with Fluid: All parts that come into contact with fluids are made from AISI 316/316L stainless steel, offering excellent resistance to corrosion and enhancing the longevity of our products.

Other Metal Parts: The metal components crafted by control valve manufacturers in India are made from 304 stainless steel, providing robust structural integrity and resistance to environmental factors.

Seal Options: As a trusted control valve manufactures in India, we offer a variety of seals to cater to different operational needs, including:

- EPDM: Our control valves with EPDM areideal for a wide range of temperatures and applications.

- Silicone: Control valves with silicone seals areknown for their flexibility and resistance to extreme temperatures.

- Viton (FKM): Viton seal control valves provide excellent chemical resistance.

- PTFE: Our control valves withPTFE seals ensure superior performance in harsh chemical environments.

Why is Delta Fittings Recognised Among The Best Control Valve Manufacturers?

As one of the leading control valve manufacturers in India, Delta Fittings is committed to providing industry-leading flow control solutions.

High-quality control valves at Competitive Prices

We offer high-quality control valves at cost-effective prices, making us a preferred choice among control valve manufacturers in India. Our commitment to quality ensures that you get the best value for your money.

Quick and Safe Delivery of Control Valves:

Delta Fittings provides quick and safe delivery of control valves through efficient logistics. As trusted control valve manufacturers in India, we understand the importance of timely delivery and ensure that your orders reach you promptly, minimizing downtime and keeping your operations running smoothly.

Expert Support for Technical Queries

Our team of experienced professionals is ready to assist you with any technical queries you may have. We have the expertise and knowledge to help you find the right solution for your needs, ensuring you get the most out of our control valves.

Decades of Expertise in the Industry

With three decades of expertise in the industry, Delta Fittings has established itself as a trusted name in control valve manufacturing. You can rely on us for high-quality products, competitive prices, quick delivery, and expert support—Trust Delta Fittings for all your needle valve application needs.

Experience Efficiency With Control Valves From Delta Fittings

Upgrade your industrial processes by using Delta Fittings’ precision fabricated control valves. We are a company with more than 33 years of experience, and we assure our clients quality and affordable prices for our products as well as fast and safe delivery. Rely on our certification with ISO 9001 standards and top-quality experience to improve your processes. Let us help you find the right solutions for reliable and innovative control valves on your today.

FAQ’s

1. What is the warranty period for Delta Fittings' control valves?

As leading control valve manufacturers in India, we offer a standard warranty period for our control valves, and extended warranties may be available based on your requirements.

2. What is the lead time for ordering control valves from Delta Fittings control valve manufacturers?

The lead time for ordering control valves may vary depending on the type and quantity of valves required. Contact us for specific lead time information.

3. Are Delta Fittings' control valves compliant with industry standards?

Yes, our control valves are designed and manufactured to meet or exceed industry standards for quality and performance.

4. Can Delta Fittings provide technical assistance for selecting the proper control valves?

As reliable control valve manufacturers, we have a technical team that can assist you in selecting the proper control valves for your specific applications and requirements.

5. Do you offer custom control valve solutions?

Yes, we specialize in providing custom control valve solutions tailored to your specific requirements and applications.